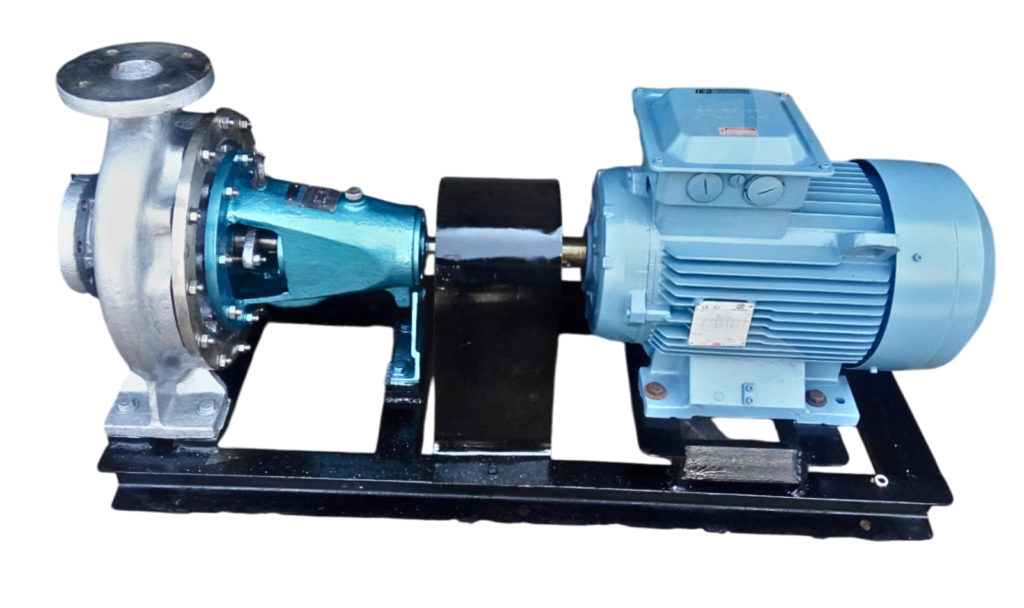

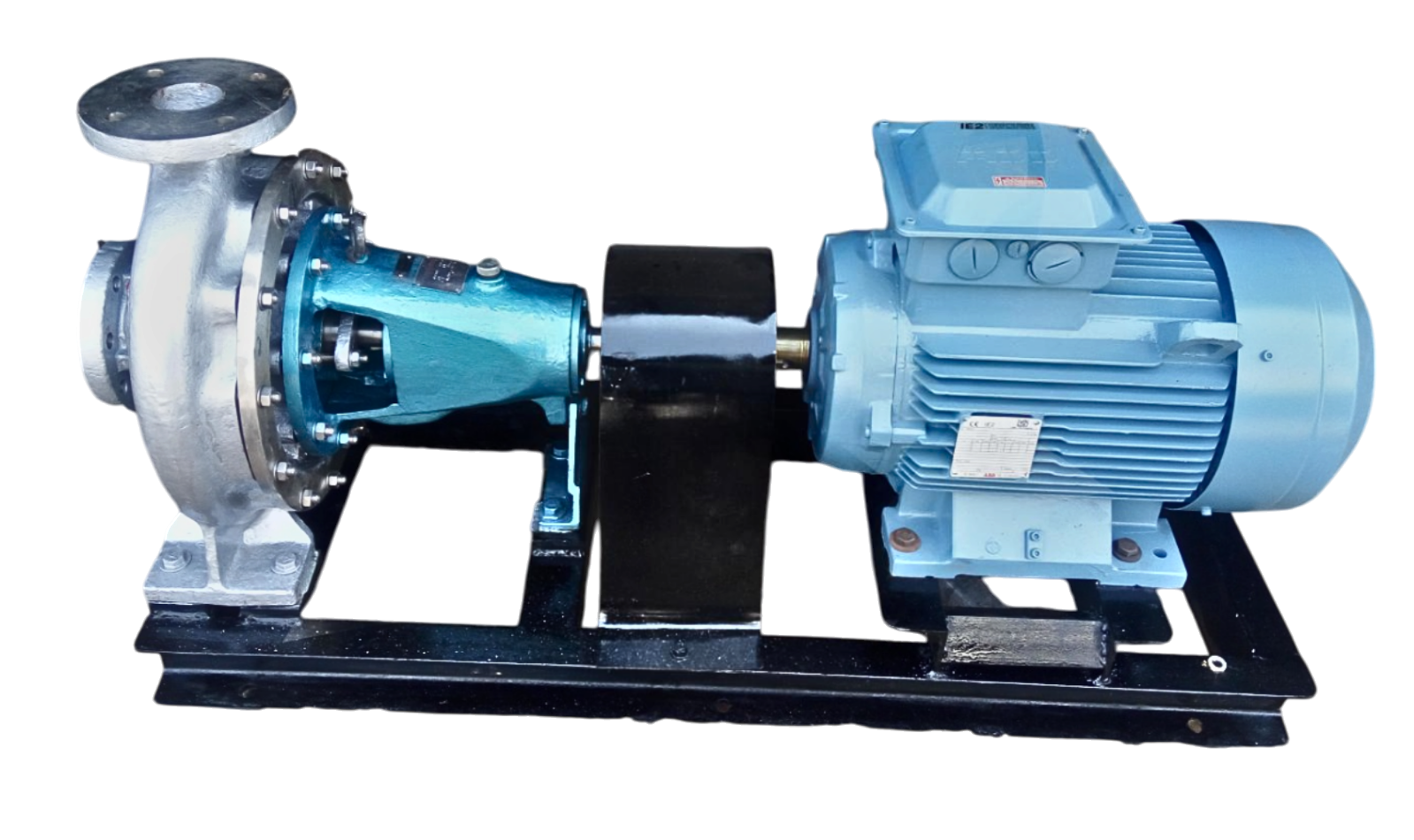

Kirti Engineering’s Chemical Process Pumps deliver superior reliability for the most demanding industrial applications. Engineered with advanced corrosion-resistant materials and precision-crafted components, our pumps efficiently transfer aggressive chemicals, solvents, and reactive compounds with exceptional flow consistency and pressure control. The carefully designed hydraulics and premium-grade mechanical seals provide outstanding performance across diverse operating conditions and chemical environments. With excellent chemical compatibility and thermal stability, these pumps serve as ideal solutions for chemical manufacturing, pharmaceutical production, and specialized industrial processing, ensuring continuous operation in critical process applications.